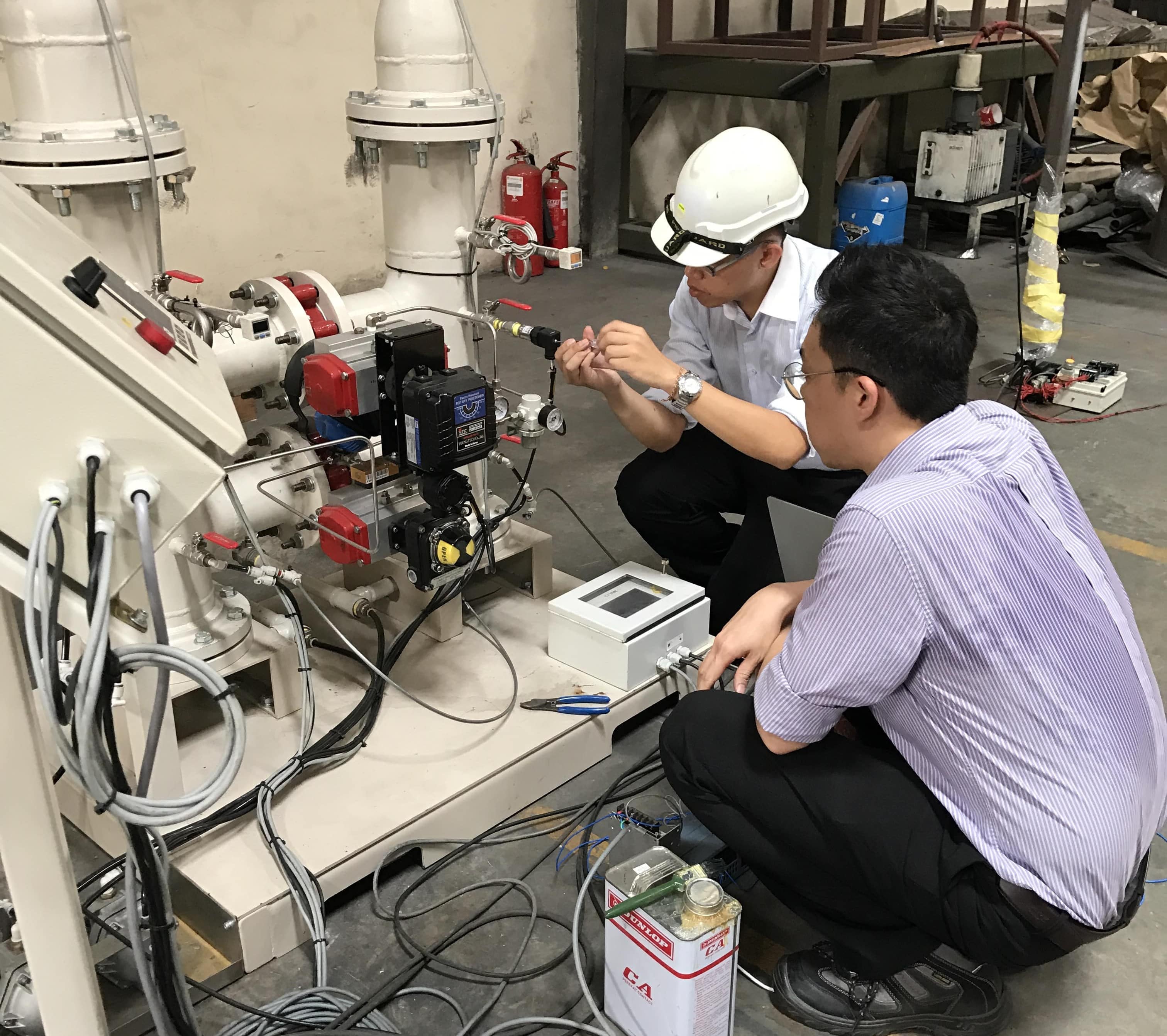

We strive to be the process control automation system provider that you can rely on. Our automation experience ranging from the Device layer (I/O Panels, Instrumentation), PLC Automation and Process Control, HMI and Operator Interface, Control Panel and SCADA. Our engineers are well experienced to keep your plant efficiency and operational excellence.

We are with the capabilities to design, build, testing, install and commission control panel based on client’s requirements. We are flexible to handle both single and complex custom control panel with quality assurance. In SCADA System Monitoring, our solutions allow our client to integrate with existing systems at multiple sites from a remote environment to the central control site. As a result, you are able to take control of your operations, the value of the process data, increase engineering efficiencies and simplify a Digital Transformations Journey.

Process control system is the first level installation of safety protection that we concern. It is the function to control the asset’s process within the design limits and prevent of any process excursion beyond the limit. Together with Process Control Automation, we offer a complete Integrated Control and Safety Systems (ICSS) to prevent from cybersecurity threats. With IEC62443 series of standards is utilized and to be use across industrial control segments and assist end users through the process of securing industrial control system.

Find out more about Process Control Solution Projects here.

Our Expertise

Process Control System

1. SCADA Systems

SCADA (Supervisory Control And Data Acquisition Systems) is a platform technology used to control and supervise industrial processes and to optimize the complex coordination of operations. SCADA systems are powerful enough to handle the complex processes required to operate the Fluid Management System. These control systems provide a stable and cost-effective solution to the needs of Hazardous Industries.

In the Oil & Gas Industry, we need operational data from the field to calibrate equipment, to schedule maintenance activities and coordinate with third-party logistics to keep the flow of product moving. SCADA systems will actually calculate the production values, generate trends for insights information and increase productivity. In the Downstream sector, the refineries often involve in receiving and refining crude oil at processing plants which SCADA system will manage and monitors the plant’s performance. SCADA is used here to supervise all area of filled instruments, through valve control system so that in case of unforeseen circumstances, SCADA system will help to ensure you have a safe operation by alerting your personnel.

Our solutions enable you to:

- Integrate with your existing systems at all sites from a distributed remote environment to the central site.

- Gain full visibility of remote SCADA Systems

- Connect to Remote PLC & RTU

- Reduce Maintenance costs and Equipment Downtime

- Increase Efficiency and Reduce Site Visits

- Manage change throughout the network, accommodating service and maintenance

2. System Migration Services

Migration is a cost-effective solution to ensure that your facilities are in good health for sustainability growth. It helps to increased data acquisition and visibility, scalable modular Systems and improved plantwide control and optimization.

Partial Migration

- Replacement of controllers

- Replacement of HMI or SCADA

- Replacement of communication network

- Replacement of field devices

Complete Migration

- Expandable communication network and interfacing devices for a higher level system like MES or SAP system

- New solution of the overall system

- Improvise productivity and quality of the process

3. Control Panel Solutions

We design, build, testing, install & commission the right control panel based on your specific requirements. Our control panel included the IP rating area classification up to and including Class 1 Div 2 hazardous area, Zone 1, 2 -panel design or fabrication with certification;

We are well experienced with the design and delivery of standard and custom panels for

- Explosion Proof Panel (EX -p, d, e, ia Panel)

- HMI Panel

- Main Distribution Board

- PLC Control Panel & Remote IO Panel

- MCC Panel

- Analyzer Panel

- MIMIC Panel

- Marshalling Panel

- Telemetry Panel

- MCC Capacitor Bank